Introduction

Many companies consistently struggle to manage their data due to the absence of a centralised system that collects all data comprehensively. Think of it like having different puzzle pieces scattered in different rooms – it’s hard to see the full picture. Just as you need all puzzle pieces in one place to complete a puzzle, companies need all their data in one spot to make good decisions. Without an industrial data platform, companies in various sectors face significant challenges managing and analysing the vast data from their assets and production processes.

Key Problems

Fragmented Sources

- Data originates from numerous sources, including sensors, cameras, and control systems throughout the factories. Each source creates information in its own way. When these sources don’t talk to each other, it’s hard to get the full picture. Factory managers can’t easily spot problems or make quick decisions because their data is split up in different places. This is like having a story written in different languages – you need to translate everything before you can understand what’s happening.

- The lack of a unified data management system leads to inconsistent formats and quality issues, making it hard to get meaningful insights.

Limited Real-Time Processing

- Numerous existing systems lack the speed to effectively handle incoming data streams promptly. This means managers often see problems too late to fix them quickly. TO make sense of the information it will have to travel far when machines can’t process data where they are generated. This creates delays that can cost time and money. Think of it like getting yesterday’s weather forecast – it’s not very helpful for planning today.

- The inability to perform edge processing often results in processing critical data far from the source, increasing latency and reducing responsiveness.

Inefficient Storage and Retrieval

- Searching for old data turns into a significant challenge when it disperses across multiple disparate systems. The system saves some information twice and might lose other important details. It’s like having important files scattered across different folders on your computer – you waste time searching instead of working. This messy storage makes it hard for companies to learn from their past and plan for the future.

Lack of Advanced Analytics and Machine Learning

- Modern factories require intelligent systems that can proactively identify potential problems. Without these tools, machines might break down without warning. This leads to costly repairs and stopped production. Smart analytics work like a health monitor for machines. They can tell when something isn’t right and help fix small issues before they become big problems. Many factories still lack these important tools.

- The lack of automated anomaly detection and predictive maintenance solutions increases downtime and maintenance costs.

Challenges in Visualisation and Reporting

- Existing systems often do not provide user-friendly and comprehensive dashboards for data visualisation., making it hard for stakeholders to interpret data and make informed decisions.

- Workers need clear, easy-to-read displays that show what’s happening in their factory. Current systems often show complex numbers and charts that are hard to understand quickly. This is like trying to read a map without any clear labels or colours. When people can’t easily spot problems on their screens, they can’t make quick decisions to fix them. Real-time updates are essential for keeping everything running smoothly.

The Architecture Review

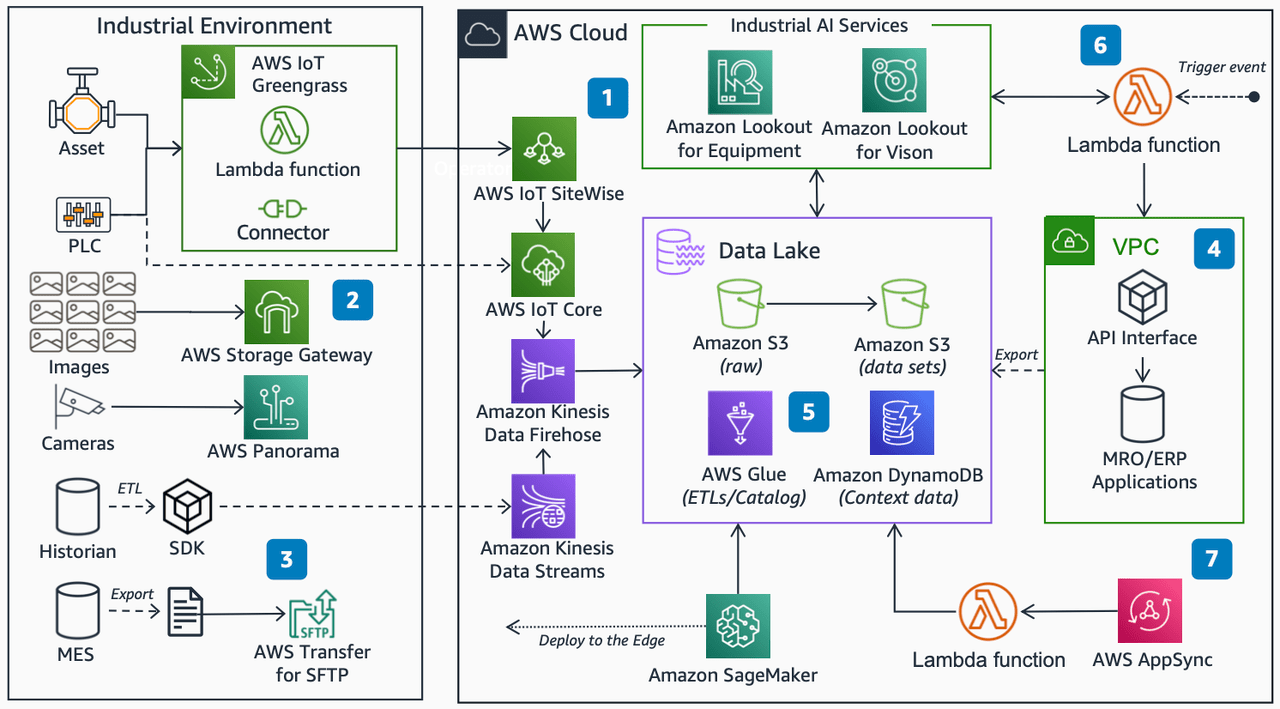

AWS has created a system that brings all the factory data together in one place. This smart design helps solve many common data problems. Let’s look at how this system works and how different industries can use it. Think of it as building blocks that fit together perfectly to create a complete picture of your factory’s performance. This reference architecture addresses data fragmentation and reliability issues effectively. Let’s explore this architecture’s key components and potential applications, evaluating its strengths and generalisability for various industrial use cases. At Yarli, we specialise in guiding and implementing such advanced factory platforms to help businesses unlock the full potential of their data.

Ingesting and Transforming Data

The system starts by collecting data from all machines in the factory. Special tools called IoT Greengrass work like translators right next to the machines. They read and sort the information straight away, which means faster responses to problems. This is like having a helper at each machine who can instantly understand and relay important messages. The system then sends this processed information to a central storage space called a data lake, where it’s kept safe and organised. The integration with IoT SiteWise via IoT Core and Amazon Kinesis Data Firehose allows for seamless streaming of IIoT data into the data lake, facilitating efficient data collection and management.

Evaluation: This approach effectively addresses the need for real-time data processing and transformation at the edge, making it highly suitable for industries requiring immediate insights from their operational data. Yarli’s expertise ensures that these integrations are seamless and optimised for your specific needs.

Synchronising and Transferring Images

Factory cameras take many pictures to check product quality and safety. Special tools help the system collect and store these images safely. AWS Panorama helps manage all the camera feeds, while Storage Gateway makes sure no important images get lost. These tools work together like a digital photo album that’s always up to date and easy to search through.

Evaluation: The use of Storage Gateway and Panorama provides a simplyfied solution for incorporating visual data, which is essential for applications such as quality control and safety monitoring in manufacturing environments. Yarli can help you implement these solutions to maximise the efficiency of your image data processing.

Streaming Manufacturing Application Data

Factory machines create lots of different information every second. The system captures this constant flow of data using tools like Amazon Kinesis Data Streams. It’s similar to recording a video of everything happening in the factory. This keeps track of all activities and helps spot any issues quickly. The system can handle different types of information, from temperature readings to production counts.

Evaluation: The ability to stream and transfer data using multiple services enhances the adaptability of the architecture, making it applicable to a wide range of manufacturing scenarios. Yarli’s tailored solutions ensure that your data streaming processes are robust and efficient.

Managing Industrial Enterprise Application Data

Using application interfaces can export Industrial enterprise application data to the data lake. Amazon S3 and Amazon DynamoDB help managing historical records and reference data, respectively. This ensures that both historical and real-time data are readily accessible for analysis.

Evaluation: The efficient management of enterprise application data and historical records using Amazon S3 and DynamoDB enhances data accessibility and reliability, supporting long-term data analysis and reporting. Yarli ensures these processes are aligned with your business goals for optimal performance.

Data Engineering and Machine Learning

AWS Glue is utilised for data engineering and cataloguing data sets in the data lake. For machine learning, Amazon SageMaker and Industrial AI services provide powerful tools for building and deploying ML models. The architecture supports initiating ML inference from Lambda functions, with results integrated into enterprise applications via API interfaces.

Evaluation: The comprehensive data engineering and machine learning capabilities offered by Glue and Amazon SageMaker ensure that the architecture can support advanced analytics and predictive maintenance applications, driving significant operational improvements. Yarli’s expertise in ML implementation ensures these models are effective and beneficial for your business.

Accessing Data Sets and Results

AWS AppSync allows dashboards and applications to access data sets and results, providing a user-friendly interface for data visualisation and decision-making.

Evaluation: The integration of AppSync for data access and visualisation ensures that stakeholders can easily interact with and derive insights from the data, enhancing the overall usability of the system. Yarli helps design and implement these interfaces to ensure maximum usability and insight extraction.

Conclusion

The AWS Industrial Data Platform brings together all the tools factories need to work smarter. It helps collect, understand, and use data from every machine and process. This system can grow with your factory and adapt to new challenges. Whether you’re running a small workshop or a large manufacturing plant, this platform can help you work more efficiently. Contact Yarli today to learn how we can help make your factory smarter and more productive.

FAQ: Industrial Data Platforms and Advanced Factory Solutions

An industrial data platform centralises data from various sources, such as sensors, cameras, and control systems, enabling factories to make informed decisions. By solving issues like fragmented data, slow processing, and inefficient storage, it ensures smoother operations and improved productivity.

Fragmentation occurs when data is scattered across multiple sources in different formats. This makes it challenging for factory managers to analyse data holistically, leading to delayed decisions and potential production inefficiencies.

Real-time processing allows immediate responses to problems, reducing downtime and maintenance costs. Without it, critical issues might only be identified after significant delays, costing both time and money.

Edge processing handles data near its source (e.g., at machines), minimising delays and ensuring timely decision-making. This is particularly beneficial for operations requiring instant data analysis and responses.

Smart analytics, powered by advanced machine learning tools, enable predictive maintenance by identifying anomalies early. This reduces unplanned downtime, avoids costly repairs, and extends the lifespan of equipment.

Many existing systems lack intuitive dashboards, making it hard for stakeholders to interpret data quickly. Clear, real-time visualisations are essential for spotting issues and ensuring efficient factory operations.

AWS employs tools like IoT Greengrass, IoT Core, and Kinesis Data Firehose to collect and process data in real-time. These tools ensure that information is sorted, transformed, and stored efficiently for analysis.

AWS Panorama and Storage Gateway manage camera feeds and image data, ensuring quality control and safety monitoring. These tools act as a centralised repository, making it easy to search and utilise visual data.

Streaming tools like Amazon Kinesis Data Streams capture and monitor real-time machine data. This helps factories track production metrics, spot irregularities, and ensure optimal performance.

AWS integrates services like Amazon SageMaker and AWS Glue for data engineering and machine learning. These tools enable predictive analytics, anomaly detection, and other intelligent operations to enhance factory productivity.

Yes, AWS uses tools like Amazon S3 and DynamoDB to manage historical and real-time data. This ensures that all relevant data is accessible for long-term analysis and strategic planning.

The AWS architecture is versatile and can be applied to various sectors, including manufacturing, energy, and logistics. Its scalability ensures it meets the unique demands of different industries.

Yarli specialises in designing and implementing advanced factory platforms. With expertise in AWS tools and industrial processes, Yarli ensures seamless integration tailored to your business needs.

Contact Yarli to learn more about AWS Industrial Data Platforms and how they can revolutionise your factory operations. Yarli offers expert guidance to unlock the full potential of your data.